3. The outmost is wooden case with fixed formwork.

4. Thebottom of the wooden case has firm iron jack, convenient to handing and transport

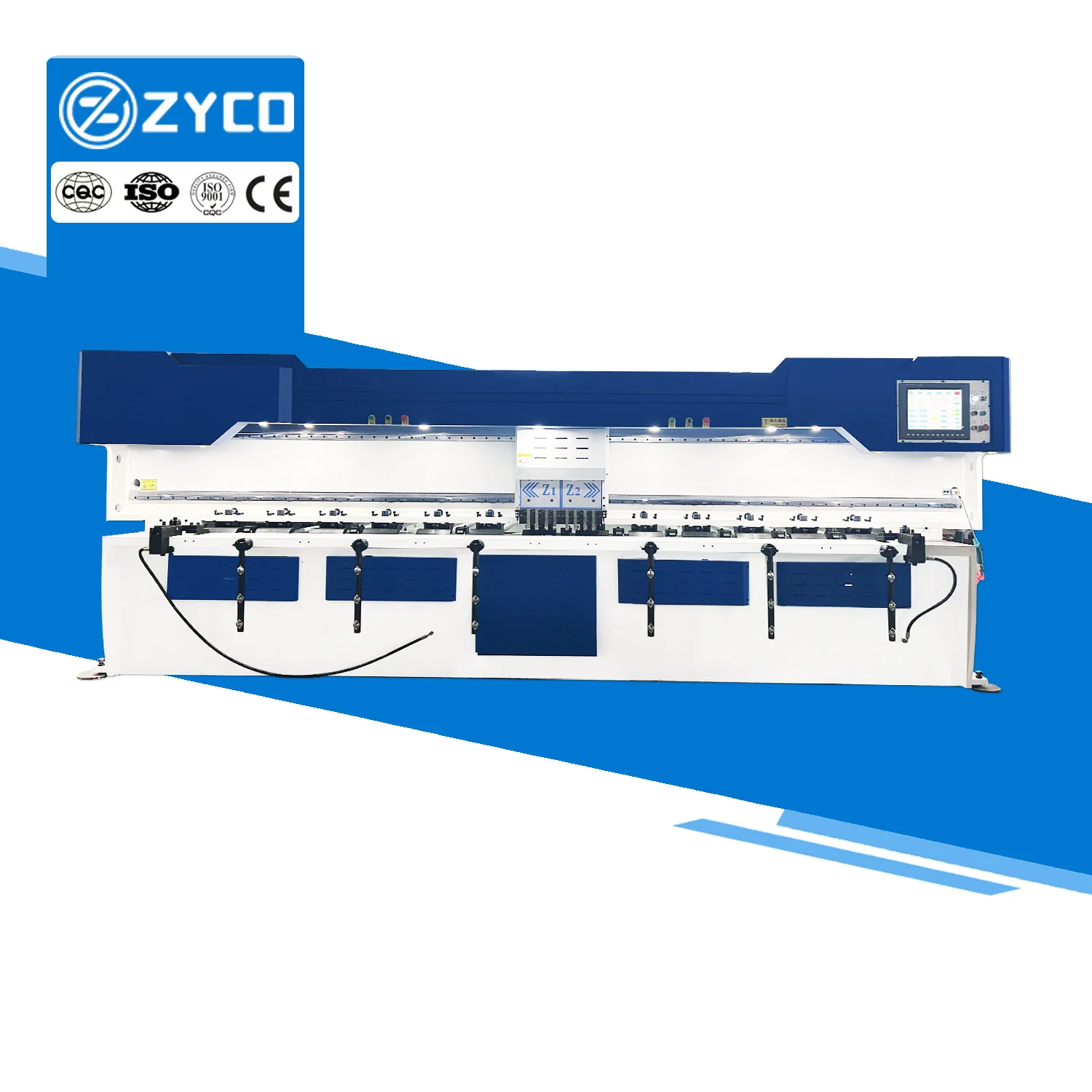

ZYCO is proud presenting their innovation latest in metal processing - the Spot Product High-Accuracy Auto Die-Cutting and V Slots 1220x3200 Metal Grooving Machine. This equipment cutting-edge set to revolutionize the manufacturing industry by giving effectiveness unparalleled precision in steel grooving and die-cutting. The Spot Product High-Accuracy car Die-Cutting and V Slots 1220x3200 Metal Grooving Machine delivers precise and accurate cuts to metal sheets rendering it a vital tool for manufacturers who require tight tolerances of their services and products using its advanced auto-die cutting technology. This revolutionary product makes utilization of sensors that could be state-of-the-art settings that are computerized make sure every cut is created completely every time. The Spot Product High-Accuracy Auto Die-Cutting and V Slots 1220x3200 Metal Grooving Machine normally made with V slots which allow manufacturers to make forms that are complex designs with ease. This particular aspect is quite beneficial in crafting intricate bits of metal and this can be crucial aspects of various products and services such as housings for electronic devices or elements for automotive components. These devices's steel grooving capability is unquestionably an addition excellent its already impressive features. With this particular function particular manufacturers are able to include grooves and ridges to metal sheets boosting their integrity structural and them more resistant to bending and breaking. Grooving can also be ideal for creating habits regarding the steel area further improving its aesthetic appeal. As being a provider reliable ZYCO has guaranteed that the Spot Product High-Accuracy car Die-Cutting and V Slots 1220x3200 Metal Grooving Machine is made in just the highest-quality materials ensuring its durability long service life and low-maintenance requirements. This machine normally made for ease-of-use permitting operators to quickly master its features and play a role in increased productivity regarding the factory flooring

Model | Spot Product High-accuracy auto die-cutting and v slots 1220x3200 metal grooving machine exporteurs leveranciers | ||

Processing Material | Stainless steel, iron plate, aluminum plate, copper plate | ||

Processing Range | Length | 4000 mm | |

Width | 8-1500 mm | ||

Thickness | 0.5-8 mm | ||

CNC System | Display | 15 inch HUST touch screen | |

Control method | 4 axes X Y Z1 Z2 | ||

Storage capacity | Store 99 groups, and slot 999 small V ports in one group | ||

Transfer method | Ball screw/linear guide/pinion and rack | ||

Hydraulic Clamping device | 1.5Kw/8L/10Mpa | ||

Processing speed | X axis slotting | 0-90 m/min Stepless speed regulation | |

Y axis back feeder | 0-90 m/min Stepless speed regulation | ||

Z1 Z2 axis tool holder | 0-20 m/min Stepless speed regulation | ||

Processing precision | X axis slotting | ±0.05 mm | |

Y axis back feeder | ±0.02 mm | ||

Z1 Z2 axis tool holder | ±0.02 mm | ||

Machine body precision | Workbench parallelism | ±0.03 mm | |

Crossbeam guide rail parallelism | ±0.03 mm | ||

Back feeder guide rail parallelism | ±0.03 mm | ||

Size | 5800 x 2100 x 2000 mm | ||

Weight | 12000 kg | ||