Title: The Amazing Hydraulic Sheet Metal Shear: Cut Through Metal Like Butter

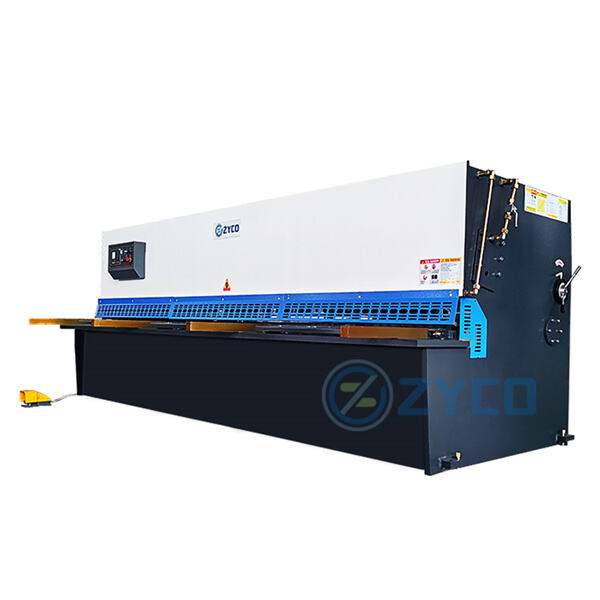

Looking for an effective tool that can effectively cut through metal with simplicity? Look no further compared to the Hydraulic Sheet Metal Shear. This ZYCO hydraulic sheet metal shear is amazing vital tool in almost any metalworker, supplying unparalleled cutting abilities and security features. We are going to explore the benefits of utilizing a Hydraulic Sheet Metal Shear its many exciting innovations, and just how to correctly and efficiently make use of one.

A Hydraulic Sheet Metal Shear has several benefits over other metal cutting tools. Above all, ZYCO shear hydraulic provides power is cutting is unparalleled. The machine is hydraulic stress is increased force, permitting more effective and accurate cutting of thicker metals. Additionally, these shears offer better control and precision, making sure the cuts are neat and every time is exact.

Another advantage of hydraulic sheet metal shears is the flexibility. They are suited to slicing through a wide range of materials, including steel, aluminum, and also some plastics. This versatility makes them an tool is indispensable any metalworker, as they possibly can manage many different various tasks.

Hydraulic sheet metal shears have undergone a change significant modern times with several exciting innovations which have made them a lot more useful. One of the most significant innovations could be the integration of computer control is numerical CNC technology. This ZYCO hydraulic metal shears enable operators to program the equipment to make cuts and this can be accurate.

Another innovation in hydraulic sheet metal shears may be the integration of laser-guided cutting. This technology utilizes lasers to provide an accurate cutting, making it easier for the operator so as to make accurate cuts. The cutting escalates that are laser-guided safety of the device since it ensures operators can easily see the cut line, decreasing the threat of damage.

When utilizing a Hydraulic Sheet Metal Shear, security is a top priority. Operators need to ensure they follow all security precautions and instructions, just like the usage of individual protective gear as gloves and attention protection.

Furthermore, operators should make sure that they follow all directions provided by the maker. These instructions can include how exactly to set the unit up, how exactly to properly operate ZYCO hydraulic metal shear machine, so when to execute upkeep.

Using a Hydraulic Sheet Metal Shear is fairly straightforward. First, the operator need to ensure that the product is securely put up. They are going to then need to load the materials to be cut and adjust the blade length and angle for the required cut.

When the product is within the place, as well as the blade angle and length are set, the operator will start the process. They shall need to ensure they are making use of the right amount and that the Hydraulic Sheet Metal Shear. After the cut is complete, the operator can get rid of the cut material and prepare the ZYCO hydraulic shearing machine for the next cut.

We a comprehensive R and D design team that conducted scientific analysis developed Hydraulic sheet metal shear and appearance of electronic components our mechanical goods. Our R and D team assist customers 24/7 online the design machines that satisfy requirements their particular needs. After sales, we'll offer customer feedback opinions, continuous innovation improvement applied make equipment more affluent with modern aesthetics more effectively assist customers production processing.

The online customer service team, comprised 20 employees is able assign Hydraulic sheet metal shear sales staff each day. They respond promptly questions from customers professionally efficiently create detailed official quotations. We treat each customer with enthusiasm sincerity. You can watch a video our manufacturing facility. We also offer airport pickup hotel check-in when visit our country.

Each machine's frame produced using large-scale equipment processing. This includes processes such Hydraulic sheet metal shear, entire procedure, sandblasting, well as welding. To make our equipment frame more durable stable, and guarantee accuracy final processing our company a complete manufacturing testing process. Our engineers inspect test the machines continuously a period of 24 hours after manufacturing of machine is finished. This ensures that client receives an equipment that in good shape.

Our team of 20 members from online service, which allocates engineers a daily basis to sales team, is able respond quickly professionally to Hydraulic sheet metal shear requests offer detailed official quotations. We deal every client with respect enthusiasm. We a video of our factory. If you're planning visit our country, we can provide airport pickup well as hotel check services