How to Improve the Efficiency of Sheet Metal Bending

Sheet metal bending is an operation of developing metal into various shapes using the press braking system. This action is used to come up with an array of products and section for different industries. The ZYCO entire procedure of bending might be time consuming and calls for accuracy and that your particular can produce the required results. Right here are guides on how to augment the potency of sheet metal bending.

Advantages

Sheet metal bending is the highly method well organized of developing. It permits for accuracy and precision in manufacturing and allows modification of products and parts. Sheet metal bending is also an affordable approach needs minimal natural materials, ensuing in reduced production costs.

Innovation

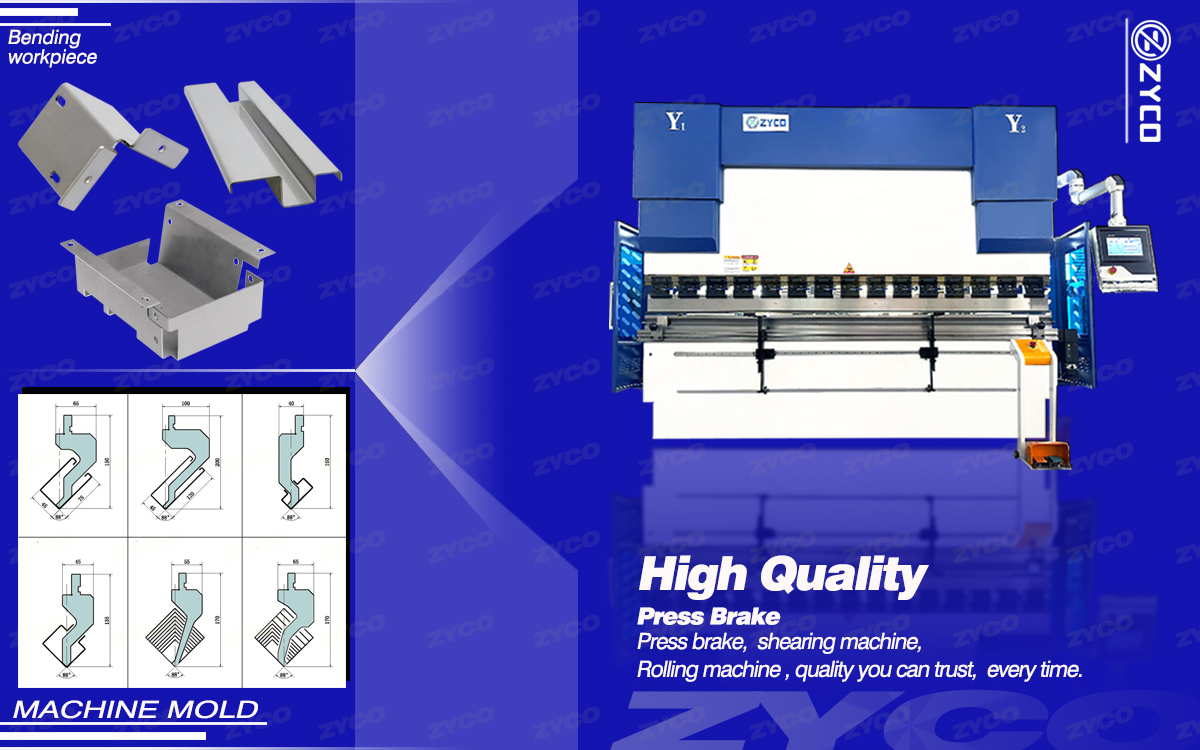

The innovation of technology has considerably affected the sheet metal bending procedure. Computer numerical control CNC) devices need revolutionized the sheet metal bending procedure by permitting for automation and increasing accuracy. CNC machines are run with a pc systems enabling for increased consistency in production and decreases the margin for mistake.

Safety

Safety is a necessary bit of procedure. Sheet metal bending requires the use of press brake system that can be dangerous should you not run precisely. It is vital that you ensure all safety measures are taken fully to prevent accidents and injuries. Proper classes and training may additionally be crucial in ensuring the safer means of brake system.

Use

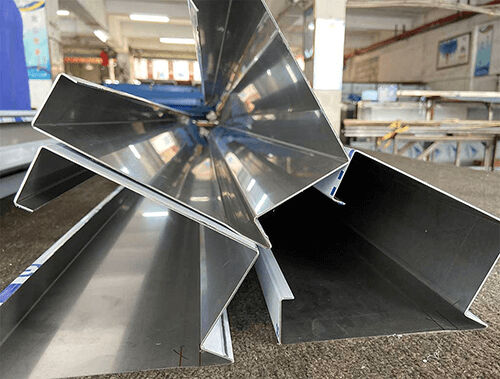

Sheet metal bending could be employed to develop wide lots of products and right parts for various organizations. These grooving machine products include nonetheless is maybe not on a automotive equipment electric gear components. Sheet metal bending is also used in to the creation of household things such as kitchen region utensils and decoration.

How to Use

The sheet metal bending procedure steps. The very action to get the appropriate material for the item or component being produced. The bending centres close step determine the fold radius angle required with this product or role. This is often determined software using manual. The sheet metal is then place in towards the press braking system the settings is used by the operator to fold the metal for their desired form.

Service

The service available in sheet metal bending is important in creating certain the final item needed specifications. This aided by the use of top quality content, precision in calculations of fold angle and radius and consistency in manufacturing. All required requirements after production, quality control measures are taken fully to render certain the last item.

Quality

Quality is an essential item of process. Sheet metal bending requires accuracy and accuracy to make certain the hydraulic machines final product necessary specs. This comprise of making certain your fold radius, angle and dimensions are all proper. Quality control measures is adopted to make sure this last system needed requirements.

Application

Sheet metal bending is found in numerous industries to generate an wide assortment of applications and components. It is the economical technique modification accuracy in manufacturing. The use of CNC devices has revolutionized the sheet metal bending procedure for increased efficiency and consistency in production. Proper training and training are very essential in ensuring safer and efficient procedure of system.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY