- Overview

- Inquiry

- Related Products

At ZYCO, we understand the importance of having high-quality, efficient tools in your metalworking arsenal. That's why we're proud to offer our ZYCO High Performance and Efficient 1250-4000 1500x400 CNC Stainless Steel Sheet Metal V Grooving Machine.

This device is built to handle even the metalworking tasks being toughest with simplicity. Featuring its motor that is effective and CNC technology, it makes quick work of perhaps the thickest, toughest sheets of stainless steels.

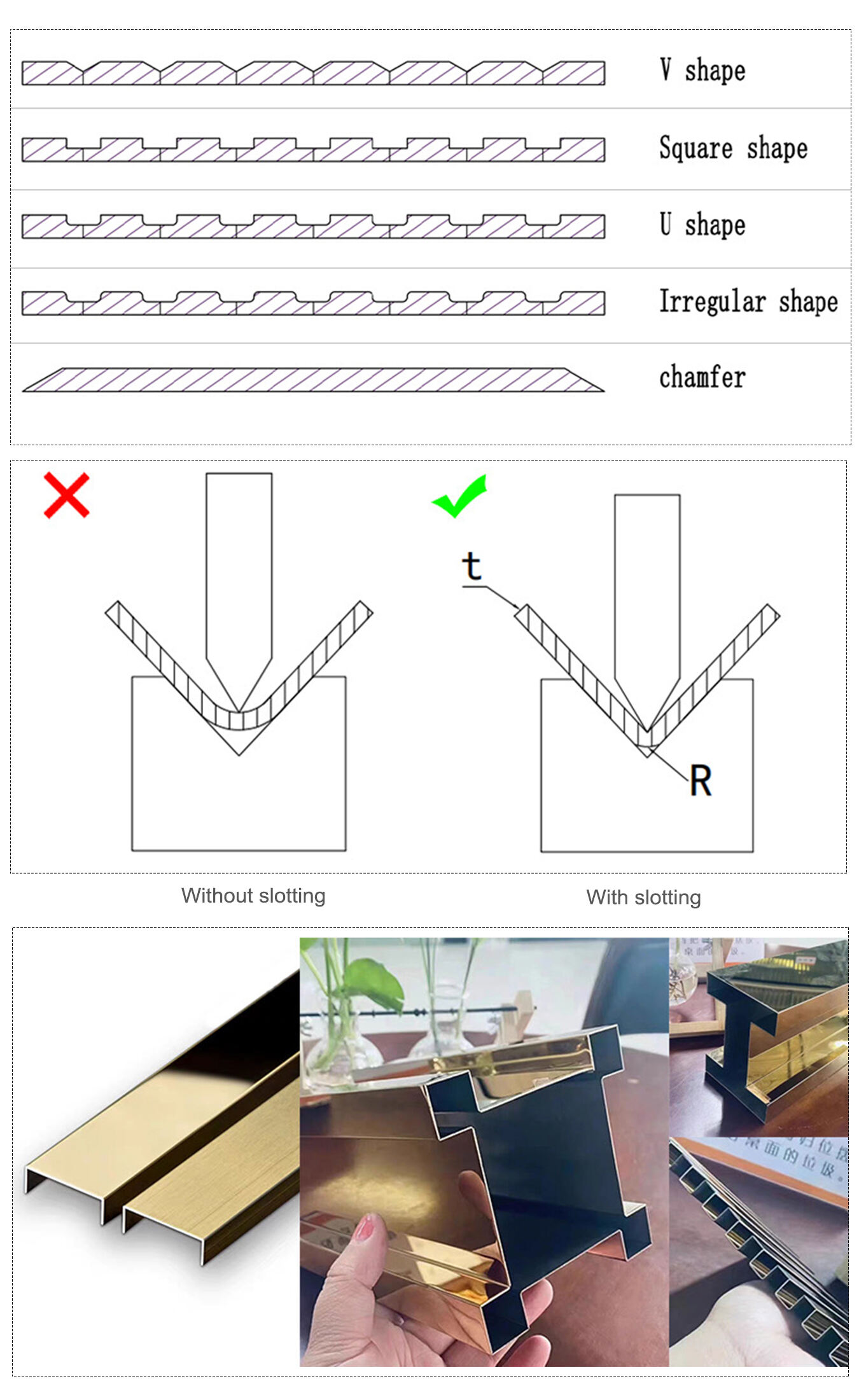

Among the key top features of this machine is its precision capabilities that are v-grooving. The machine was created to produce clean, well-defined V-grooves in your metal sheets, with consistent precision and repeatability. Each and every time whether you are working on just one sheet or even a large batch of them, this device provides constant outcomes.

That is also extremely efficient as well as its precision V-grooving abilities. Its advanced CNC settings let it consistently work quickly and, with just minimal downtime or errors. What this means is you may get your metalworking tasks done faster and more efficiently, without having to sacrifice precisions or quality.

Another advantage that is key of machine is its flexibility. It's designed to work with a number of stainless-steel sheet sizes and thicknesses, for a variety of different tasks in order to make use of it. Additionally, its compact design means it generally does not take a great deal up of space in your workshop, rendering it an ideal choice for smaller workspaces or mobile metalworking operations.

Overall, if you're looking for a high-performance, efficient, and versatile metalworking tool, the ZYCO High Performance and Efficient 1250-4000 1500x400 CNC Stainless Steel Sheet Metal V Grooving Machine is an excellent choice. With its precision V-grooving capabilities, advanced CNC controls, and efficient design, it's sure to become a valuable tool in your metalworking arsenals.

No. | Component Name | Brand |

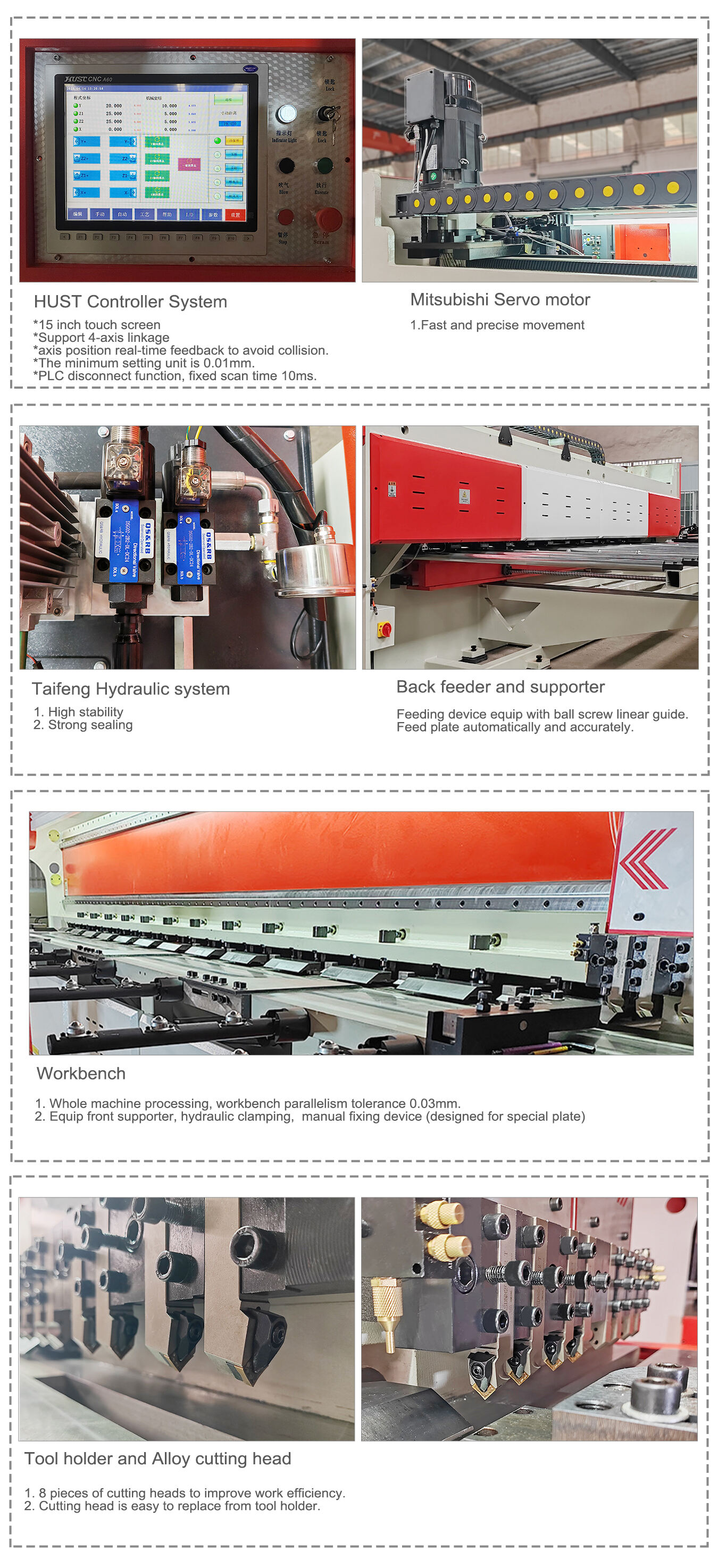

1 | Controller | HUST, China Taiwan |

2 | Servo motor and Driver | Mitsubishi, Japan |

3 | Hydraulic system | Taifeng, China Shandong |

4 | Hydraulic cylinder | Taifeng, China Shandong |

5 | Cylinder sealing element | NOK, Japan |

6 | Electrical components | Schneider, France |

7 | Ball screw and linear guide | HIWIN, China Taiwan |

8 | Plane bearing | NSK, Japan |

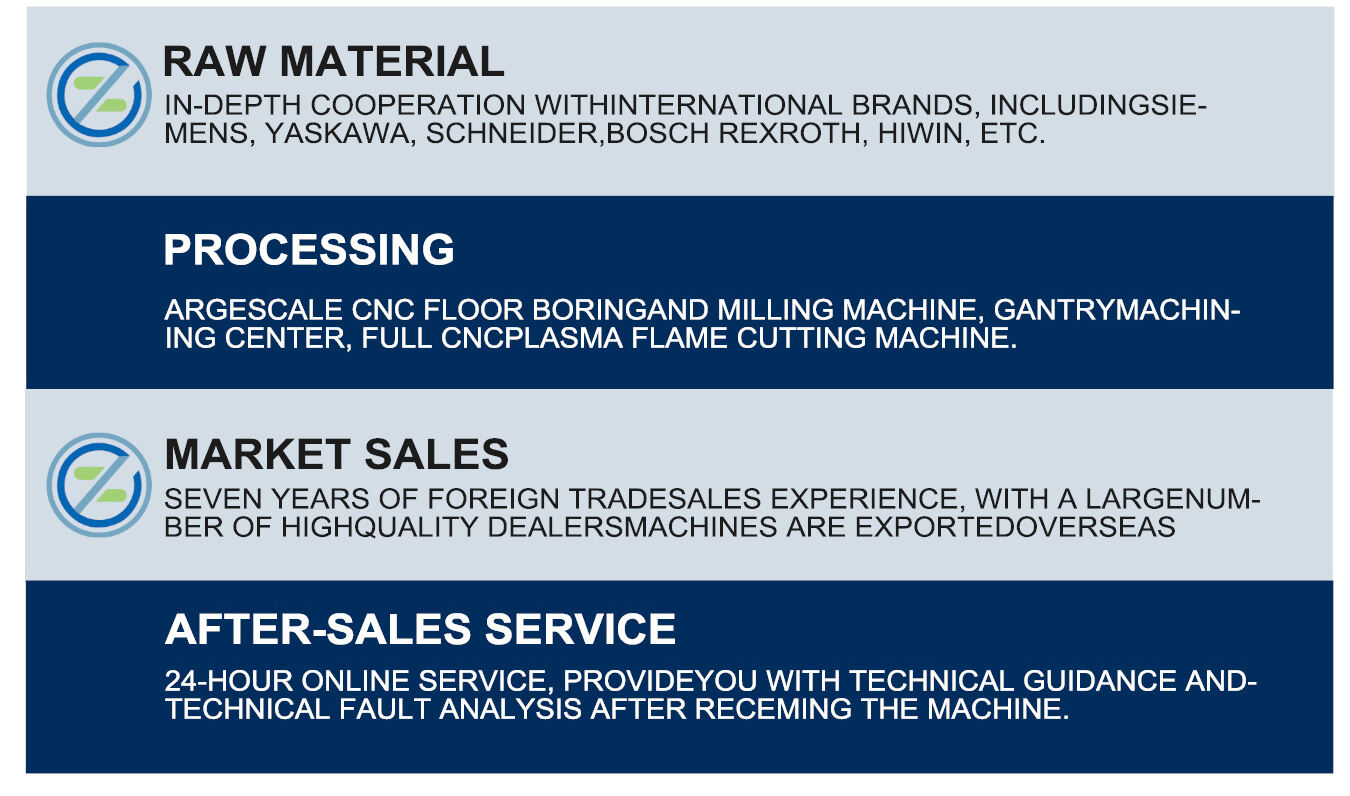

9 | Tool holder | PSDNN2020K12, China |

10 | Alloy cutting head | KORLOY/TaegUTec, South Korea |

11 | White steel knife | ASSAB 17, Sweden |

12 | Single/Double Pole Air Switch | LS, South Korea |

13 | Towline cable | IGUS, Germany |

Model | ZC-Vertical 1500-4000 | |

Processing material | stainless steel, iron plate, aluminum plate, copper plate | |

Processing Range | Length | 4000 mm |

Width | 8-1500 mm | |

Thickness | 0.5-8 mm | |

CNC System | Display | 15 inch HUST touch screen |

Control method | 4 axes (X Y Z1 Z2) | |

Storage capacity | Store 99 groups, and slot 999 small V ports in one group | |

Transfer method | Ball screw/linear guide/pinion and rack | |

Hydraulic Clamping device | 1.5Kw/8L/10Mpa | |

Processing speed | X axis (slotting) | 0-90 m/min (Stepless speed regulation) |

Y axis (back feeder) | 0-90 m/min (Stepless speed regulation) | |

Z1 Z2 axis (tool holder) | 0-20 m/min (Stepless speed regulation) | |

Processing precision | X axis (slotting) | ±0.05 mm |

Y axis (back feeder) | ±0.02 mm | |

Z1 Z2 axis (tool holder) | ±0.02 mm | |

Machine body precision | Workbench parallelism | ±0.03 mm |

Crossbeam guide rail parallelism | ±0.03 mm | |

Back feeder guide rail parallelism | ±0.03 mm | |

Size | 5800 x 2100 x 2000 mm | |

Weight | 12000 kg | |

A:Video line of our factory or we send you the video directly.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY