Do you know the origin of the tonnage of the Press Brake?

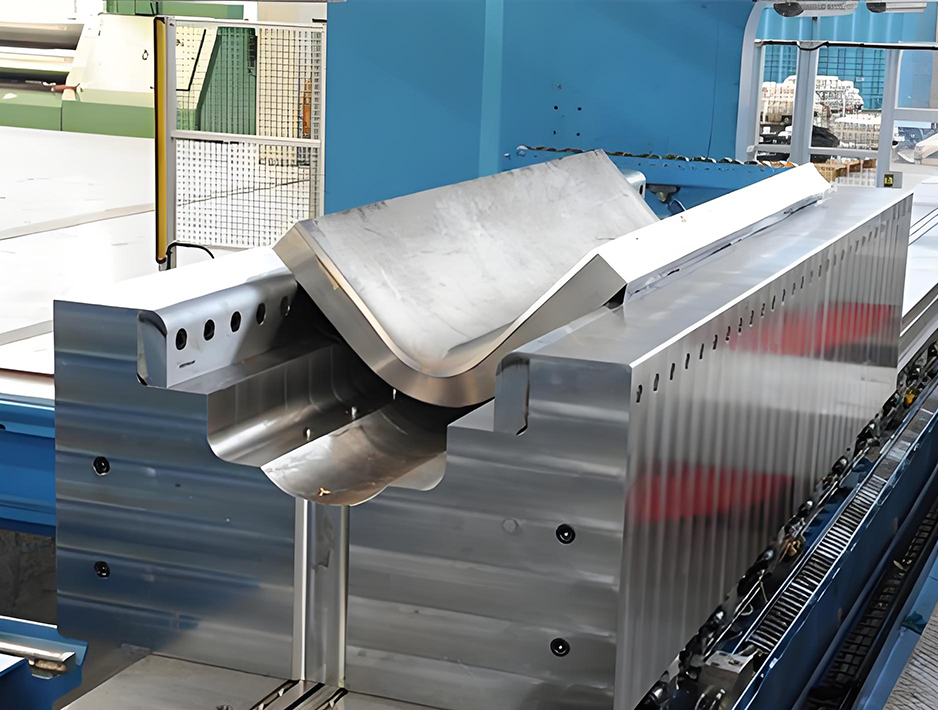

Do you want to know the whole story about press brake tonnage? In fact, let me tell you exactly that. This incredible machine from ZYCO is actually a piece of equipment used to bend steel plates into various shapes and sizes.

The tonnage capacity of the Press Brake mainly refers to the maximum pressure that the equipment can exert. Normally, the larger the tonnage, the thicker the metal sheet that can be processed, and the stronger the processing capability. The tonnage of common bending machines is generally between 30 tons and 400 tons.

To choose the appropriate Press Brake tonnage, you need to consider the following key factors:

1. Thickness of the material to be processed: According to the thickness of the metal sheet that needs to be processed, select a Press Brake of corresponding tonnage. A tonnage capacity that is too small may not be able to accomplish the required bending.

2. Product size and shape: Different products have different size and bending shape requirements, which will also affect the tonnage selection of the bending machine. Larger products typically require higher tonnage press brakes.

3. Production efficiency: The larger the tonnage, the shorter the time required for a single bending, thus improving the overall production efficiency. But at the same time, equipment investment costs will also increase.

Factors affecting stress:

1. Metal plates, of which common ones include carbon steel plates, stainless steel plates, and aluminum plates. Different materials will directly affect the pressure required for bending.

2. The width of the metal plate, the longer the metal plate, the greater the bending pressure required.

3. Mold, the mold is an important factor in calculating the bending pressure. The larger the notch of the lower mold, the smaller the required bending pressure, but at the same time the bending arc will also increase. What needs to be noted here is that the lower mold The selection of the mold notch should not be less than 8 times the plate thickness.

To sum up, before we choose a bending machine, we need to clearly know the characteristics of our products. Among them, the plate material, plate width, and plate thickness are the most important. After understanding this, we can inform the machine manufacturer, and the manufacturer can recommend the most suitable machine for us, so that our efficiency and cost-effectiveness will be improved.

Recommended Products

Hot News

-

Purpose of Grooving machine

2024-07-24

-

Indonesia-WC67K 160T 2500 CNC Press Brake

2024-07-19

-

Problems and solutions of the cylinder of the torsion axis Press Brake not working

2024-07-16

-

Common problems and solutions for the back gauge of the Press Brake

2024-07-12

-

How should we choose between hydraulic Guillotine Shearing Machine and hydraulic Swing Beam Shearing Machine?

2024-07-08

-

Why choose 8+1 axis CNC Press Brake?

2024-07-02

-

Dual-machine linkage Electro-hydraulic Press Brake - The key technology to improve metal processing efficiency

2024-06-28

-

India-WE67K 130T 3200 CNC Press Brake

2024-06-21

-

The difference between three-roller plate rolling machine and four-roller plate Rolling machine

2024-06-14

-

Discussion on CNC follow-up support technology of Press Brake

2024-06-07

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY