How to choose the most suitable bending machine based on our sheet metal products

In the sheet metal processing industry, the Press Brake is a very important equipment used for the bending processing of sheet metal products. Choosing the most suitable bending machine is crucial to improving production efficiency and product quality. This article will introduce some key factors to help you choose the most suitable press brake for you based on the characteristics of your sheet metal products.

1. Understand the materials and thickness of sheet metal products

Different sheet metal products use different types and thicknesses of materials. Usually stainless steel, carbon steel, and aluminum plates are the most widely used. When choosing a bending machine, you must first understand your commonly used sheet metal materials, thickness range and maximum length. These are important factors that affect the pressure of the bending machine. Ensure that the selected Press Brake can handle your sheet metal product materials and thickness.

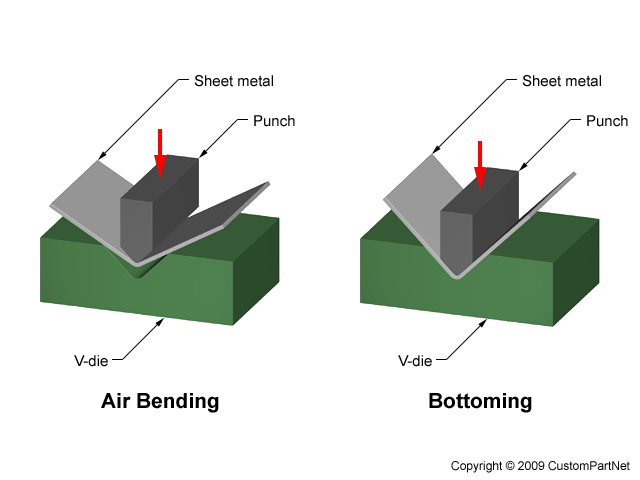

2. Consider the bending angle and bending radius

The bending angle and bending radius of sheet metal products are also important factors in choosing a bending machine. Some bending machines have a wider bending angle range and smaller bending radius capabilities, suitable for products that require more complex bending shapes. Therefore, you need to choose the appropriate bending machine according to your product requirements.

3. Consider production volume needs and work efficiency

Production needs and work efficiency are also factors that need to be considered when selecting a bending machine. If your production needs are large and you need to produce sheet metal products in large quantities, you can choose a CNC bending machine with higher working speed and automation functions. Automated features can increase production efficiency and reduce labor costs. At the same time, the stability and accuracy of the equipment must also be considered to ensure stable operation for a long time.

4. Understand additional functions

Many press brakes have additional features. For example, some bending machines are equipped with CNC systems that can achieve precise bending control and programmed operations, including multi-axis control. Some bending machines also have bending force feedback systems, which can monitor and adjust the bending force in real time to improve product quality. According to your special needs, choose a suitable bending machine with additional functions and special functions.

5. Consider budget and after-sales service

Budget and after-sales service are also factors to consider when choosing a press brake. The price of the bending machine depends on the model, brand and different configurations. When choosing, you should make a reasonable purchase plan based on your own budget. In addition, it is also important to understand the supplier's after-sales service and technical support to ensure that repair and maintenance support can be obtained in a timely manner.

6. Mold selection

There are many types of molds. If you have a special-shaped workpiece, you need to design the corresponding mold shape according to the workpiece. Commonly used molds include double V concentric molds, square multi-V molds, straight upper mold, sharp upper mold, and gooseneck upper mold. These are all suitable for Tools for various sheet metal bending

Recommended Products

Hot News

-

Purpose of Grooving machine

2024-07-24

-

Indonesia-WC67K 160T 2500 CNC Press Brake

2024-07-19

-

Problems and solutions of the cylinder of the torsion axis Press Brake not working

2024-07-16

-

Common problems and solutions for the back gauge of the Press Brake

2024-07-12

-

How should we choose between hydraulic Guillotine Shearing Machine and hydraulic Swing Beam Shearing Machine?

2024-07-08

-

Why choose 8+1 axis CNC Press Brake?

2024-07-02

-

Dual-machine linkage Electro-hydraulic Press Brake - The key technology to improve metal processing efficiency

2024-06-28

-

India-WE67K 130T 3200 CNC Press Brake

2024-06-21

-

The difference between three-roller plate rolling machine and four-roller plate Rolling machine

2024-06-14

-

Discussion on CNC follow-up support technology of Press Brake

2024-06-07

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY