Tips for use Hydraulic Press Brake

Introduction:

Hydraulic press brake is a tool widely evaluated in the sheet metal processing industry. It applies pressure and bending force to sheet metal to produce the desired curved shape. Then, to fully utilize the important functions of the press brake, mastering some usage tips and tricks is the key to this article. You will be introduced to some key tips and tricks to help you better use your hydraulic press brake.

1. Make sure you have the correct working parameters of the machine:

Before using the press brake, be sure to be familiar with the machine's technical parameters and working specifications. Understand parameters such as maximum bending capacity, maximum pressure and maximum stroke to properly set up the machine and avoid overloaded operation. If your machine is a CNC press brake, you need to master the use of the CNC system. In addition, ensure the safety of the work area and prevent other people from approaching the operating area.

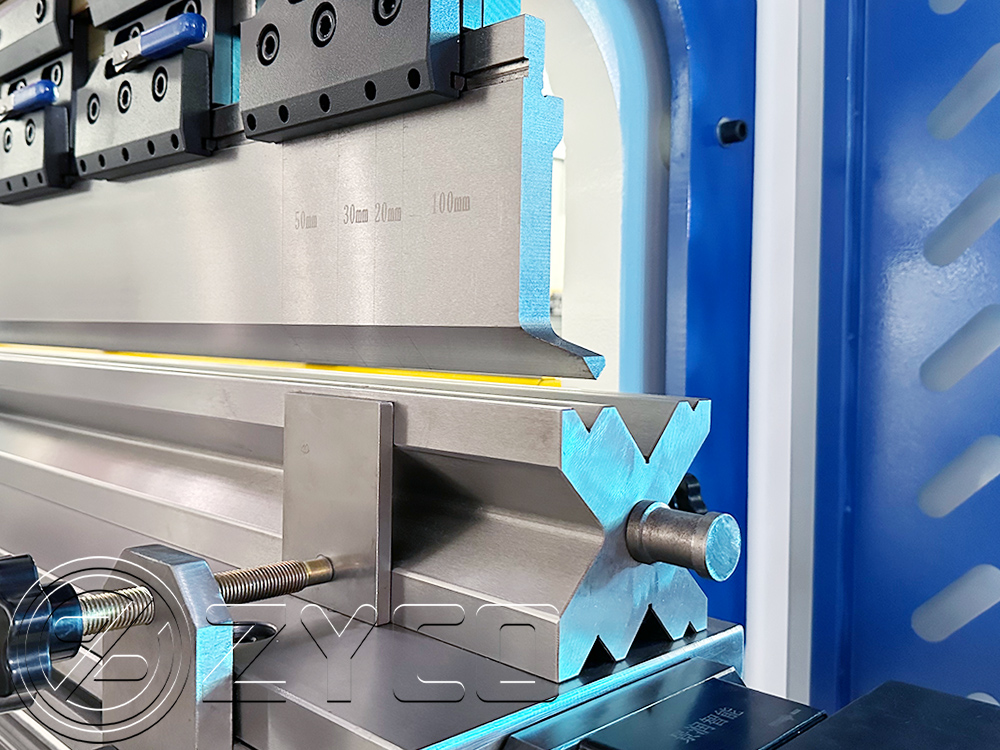

2. Select the appropriate mold:

Depending on the desired bend shape and the thickness of the metal sheet, selecting the correct die slot is also key in bending work. The quality and fit of the mold are crucial to obtain ideal bending results. Clean and maintain the mold regularly to maintain mold accuracy, extend its service life and improve work efficiency.

3. Correctness of workpiece:

Place the workpiece on the hydraulic press brake and ensure that the surface of the workpiece is clean, flat and free of debris. The correct workpiece can ensure the bending accuracy and stability of the bending machine, and also protect the mold.

4. Control bending pressure:

If you are using an electro-hydraulic CNC press brake, you can adjust the pressure of the hydraulic press brake according to the type and thickness of the metal sheet. Excessive pressure may damage the workpiece or machine. Gradually increase the pressure to ensure a stable bending process, and make fine adjustments as needed. Generally, electro-hydraulic press brake have the function of automatically calculating the bending pressure based on the thickness and width of the plate.

5. Regular maintenance and upkeep:

Regular maintenance and upkeep of the hydraulic press brake is the key to ensuring its normal operation and extending its service life. Clean and lubricate the machine's moving parts, check hydraulic systems for pressure and leaks, and replace worn parts. You can also ask our after-sales personnel for specific details, and then perform maintenance and upkeep on the machine after learning the correct maintenance instructions.

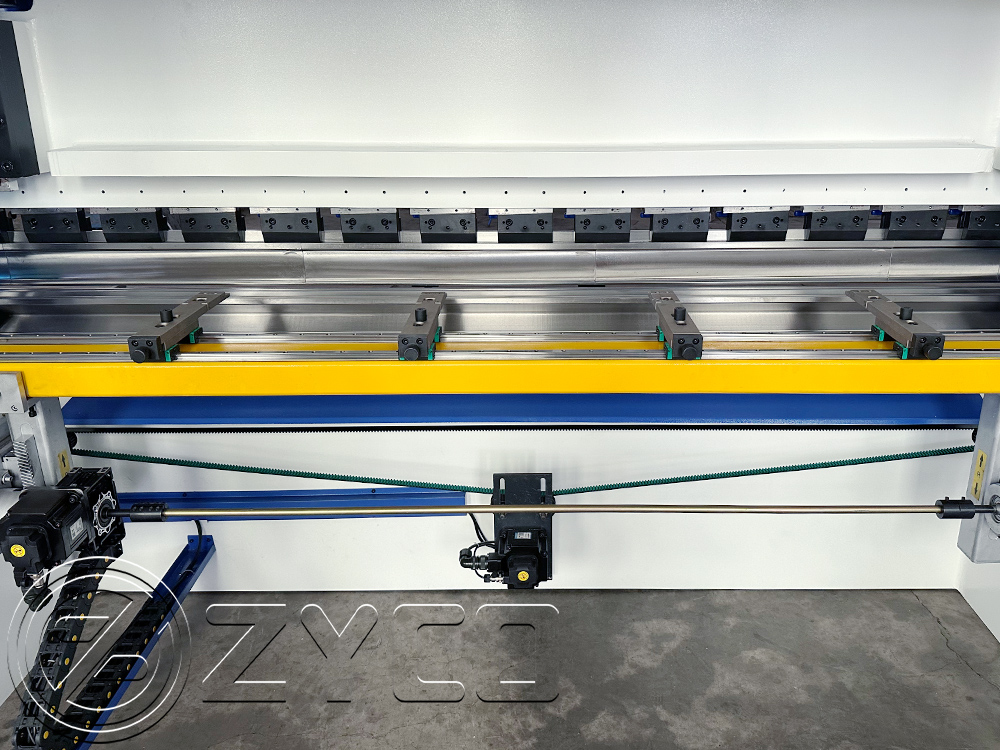

6. Regularly eliminate errors and adjust the back gauge:

The backgauge is the most critical part of the bending machine. The dimensional accuracy of bending sheet metal depends entirely on the accuracy of the backgauge and the fingers. On the premise of ensuring that the upper mold and the lower mold are concentric, the distance between the stopper finger and the center of the mold can be measured to adjust the accuracy of the backgauge so that it can reach the highest standard of straightness. First, adjust the straightness of the beam in the back gauge, and then adjust all the stop fingers to the same value.

In conclusion:

Hydraulic press brake are indispensable tools in the sheet metal industry, enabling precise bending of sheet metal. By mastering the correct usage tips and tricks, you can improve the efficiency of your bending work, obtain better workpiece products, and ensure the safety of your operations. Here, after reading this article, please try to follow some of the standard operating guidelines we have proposed, continue to practice and improve your skills, and become a skilled hydraulic press brake operator.

Recommended Products

Hot News

-

Saudi Arabia-WC67K 300T 4000 CNC Press Brake & QC12k-6×3200 Shearing Machine

2024-07-27

-

Purpose of Grooving machine

2024-07-24

-

Indonesia-WC67K 160T 2500 CNC Press Brake

2024-07-19

-

Problems and solutions of the cylinder of the torsion axis Press Brake not working

2024-07-16

-

Common problems and solutions for the back gauge of the Press Brake

2024-07-12

-

How should we choose between hydraulic Guillotine Shearing Machine and hydraulic Swing Beam Shearing Machine?

2024-07-08

-

Why choose 8+1 axis CNC Press Brake?

2024-07-02

-

Dual-machine linkage Electro-hydraulic Press Brake - The key technology to improve metal processing efficiency

2024-06-28

-

India-WE67K 130T 3200 CNC Press Brake

2024-06-21

-

The difference between three-roller plate rolling machine and four-roller plate Rolling machine

2024-06-14

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY